- Home

- About Us

- Products

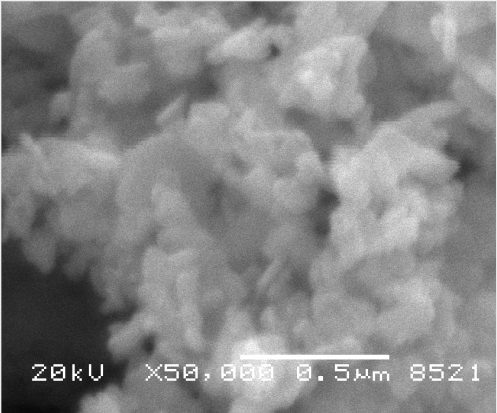

- Metal Nanoparticle

- Silver Nanoparticle

- Gold Nanoparticle

- Copper nanoparticle

- Chromium Nanoparticle

- Titanium Nanoparticle

- Iron Nanoparticle

- Zinc Nanoparticle

- Cobalt Nanoparticle

- Boron Nanoparticle

- Nickel Nanoparticle

- Tin Nanoparticle

- Tungsten Nanoparticle

- Niobium Nanoparticle

- Molybdenum Nanoparticle

- Aluminum Nanoparticle

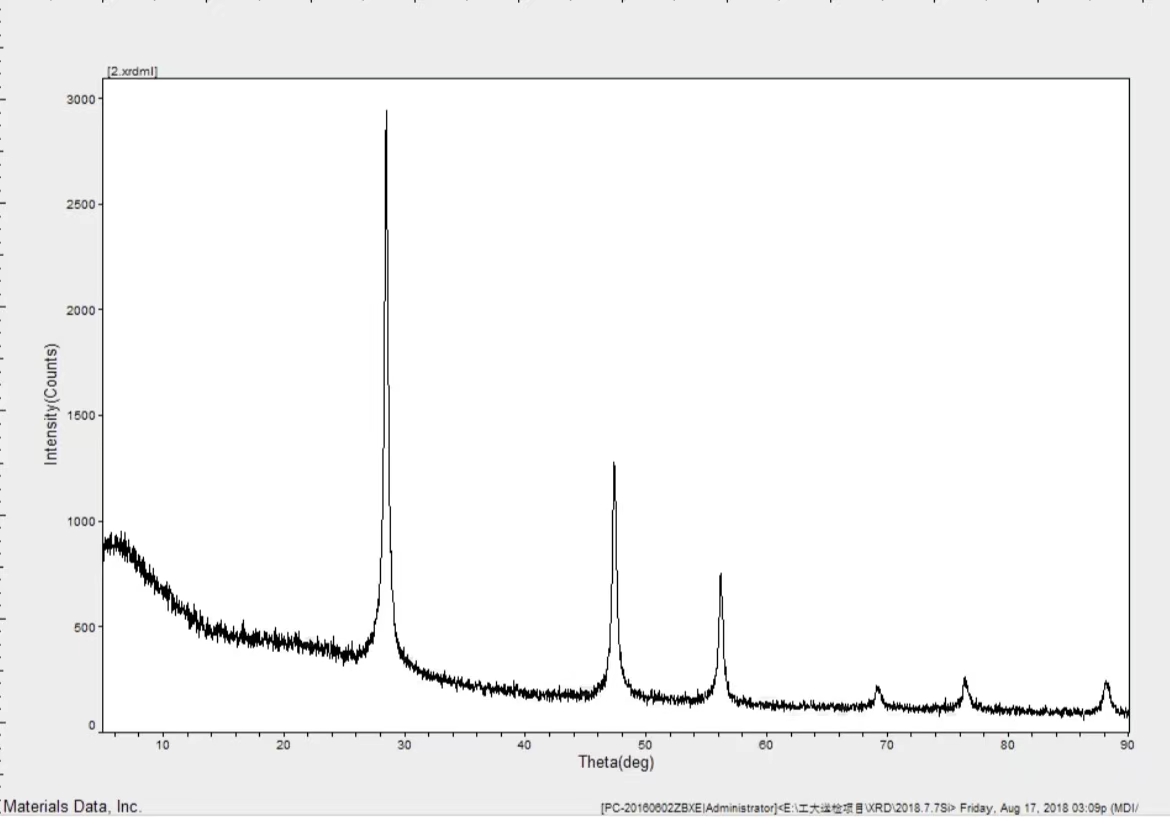

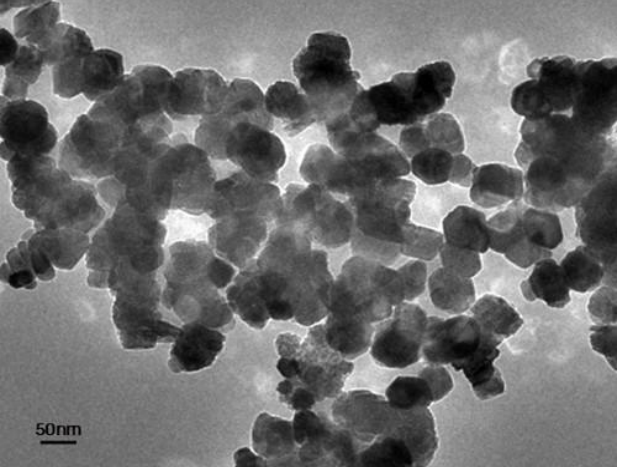

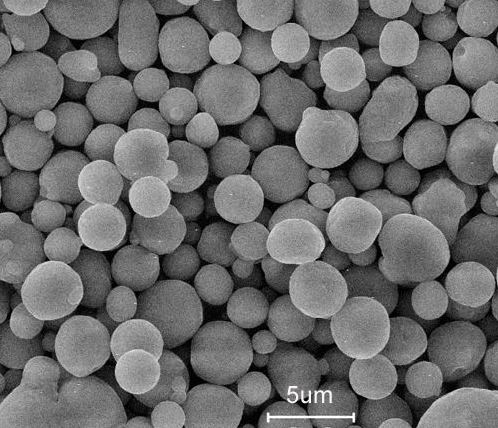

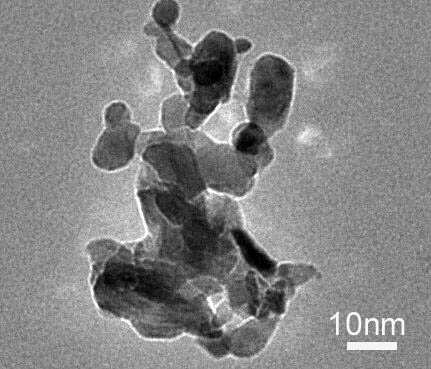

- Silicon Nanoparticle

- Zirconium Particle

- Precious Metal Powder

- Metal Alloy Nanoparticle

- Dispersion and Colloidal

- Metal Oxide Nanoparticle

- Copper Oxide Nanoparticle

- Titanium Dioxide Nanoparticle

- Zinc Oxide Nanoparticle

- Manganese Dioxide Nanoparticle

- Tin Dioxide Nanoparticle

- Bismuth Oxide Nanoparticle

- Nickel Oxide Nanoparticle

- ITO Nanoparticle

- Magnesium Oxide Nanoparticle

- Cobalt Oxide Nanoparticle

- Iron Oxide Nanoparticle

- Zirconium Dioxide Nanoparticle

- ATO Nanoparticle

- Silica Nanoparticle

- Tungsten Oxide Nanoparticle

- Molybdenum Trioxide Nanoparticle

- Vanadium Dixoide Particle

- Ta2O5 Nanoparticle

- Boron Trioxide Nanoparticle

- Multimetal Oxides Powder

- aluminum oxide nanoparticle

- Rare earth nano powder

- Compound Nanoparticle

- Nanowires and Whisker

- Carbon Nanotube

- 3D Printing Powder

- Other Nano Material

- Metal Nanoparticle

- News

- FAQs

- Send Inquiry

- Contact Us